Automatic Rigid Chocolate Boxes Machine HM-ZD6418E

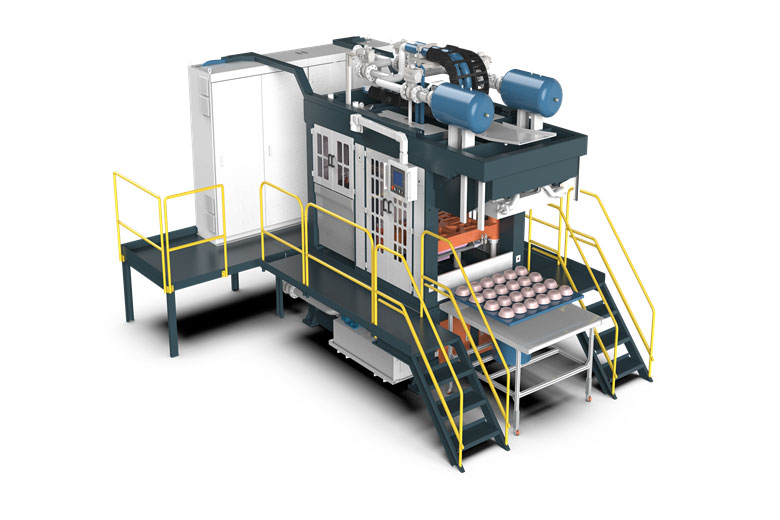

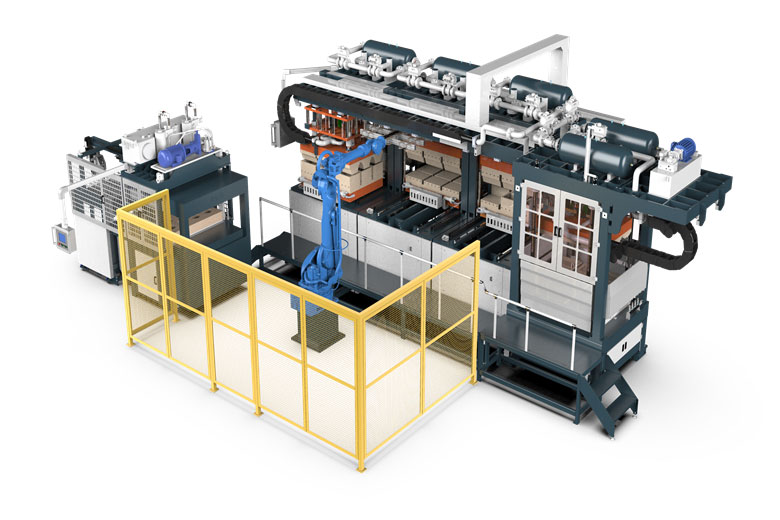

Automatic Rigid Chocolate Boxes Machine HM-ZD6418E / HM-ZD6418C is suitable to make various big size premium boxes’mass production, such as shoe boxes, mobile phone boxes, wine boxes, slanting boxes(option), slipcase boxes (option), and clamshell boxes (option), etc. The wrapped box’s max height is 190mm (C) and 130mm(E), with max folding-in depth being 100mm. It was published in 2012

Description:

HM-ZD6418E / HM-ZD6418C Automatic Rigid Box Machine is suitable to make various big size premium boxes’mass production, such as shoe boxes, mobile phone boxes, wine boxes, slanting boxes(option), slip case boxes (option), and clamshell boxes (option), etc. The wrapped box’s max height is 190mm (C) and 130mm(E), with max folding-in depth being 100mm.

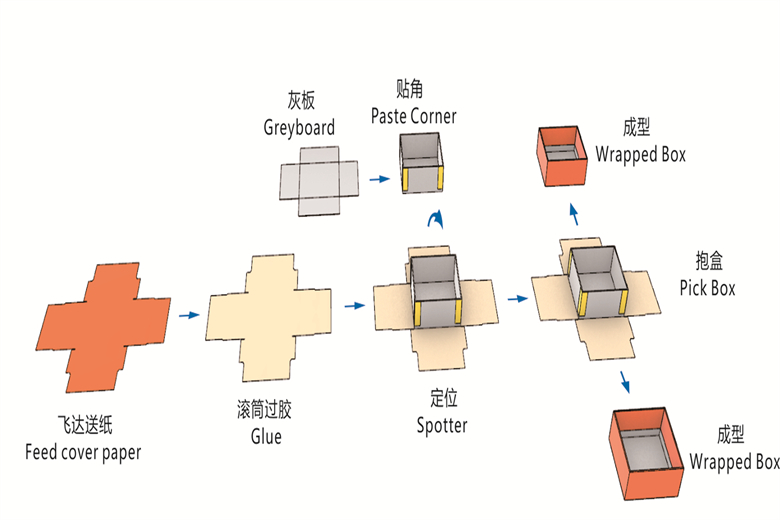

HM-ZD6418E / HM-ZD6418C adopts PLC and man-machine control, electric eye tracing system, hydraulic rectifying system, and can automatically feed cover paper, feed greyboard, paste four corners, spot greyboard, lift box, fold corner edges and wrap box. The feeder, the gluer and the conveyor are driven by servo which has continuously variable transmission and enjoys high accuracy, easy adjusting, and high efficiency. Double color conveyor can avoid changing to other color belt, which is Hongming’s patent. The spotting unit adopts Switzerland micro throttle valve, high accuracy lead-screw (c) or square tooth lead-screw (E) for rectifying, enhancing the spotting accuracy to±0.02mm. The forming unit employs THK linear slider and virtual electronic cam driving system, guaranteeing the stable quality

and fluent movement.

Features:

1. Suit to all kinds of rigid boxes in mass production;

2. Parameter adopts computer digital setting;

3. Auto error stop and display;

4. Automatic feed paper and greyboard;

5. 24-hours control for glue pre-heating;

6. Wrapper can input 300 product formulas;

7. Corner pasting part with independent man-machine control and

heating system

8. Adopt YASKAWA servo control system;

9. Spotter by electric eye tracing system and hydraulic pneumatic

rectifying system to spot correctly (spotting accuracy ±0.2mm);

10. Wrapper can automatic lift and wrap box;

11. Automatic control system for glue viscosity (optional).

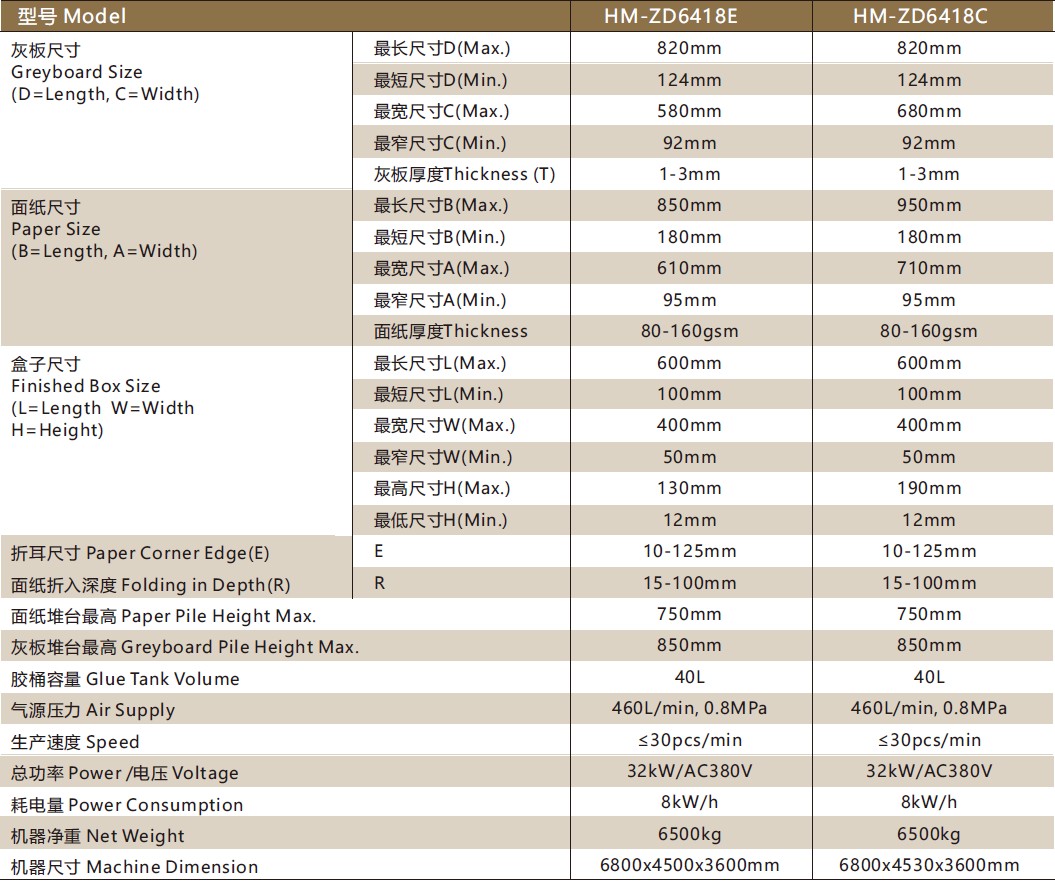

Technical Parameters:

Automatic Rigid Chocolate Boxes Machine HM-ZD6418E Workflow

Get a Cost-Effective Box Making Machine Solution

Looking for an affordable and efficient solution for your box making needs? Look no further than our cost-effective box making machines. Our machines are designed to provide high-quality, reliable performance at a price point that won’t break the bank. With advanced features and intuitive controls, our machines make box production easy and efficient. So why wait? Contact us today to learn more about how our box making machines can help you streamline your operations and save you money.