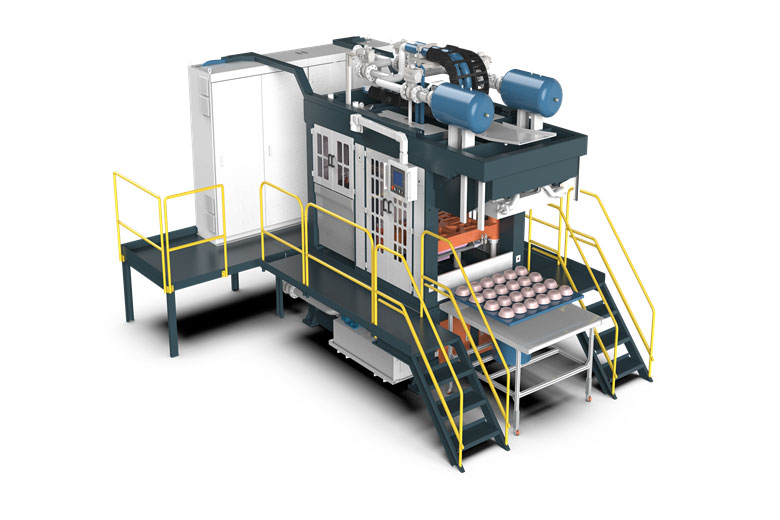

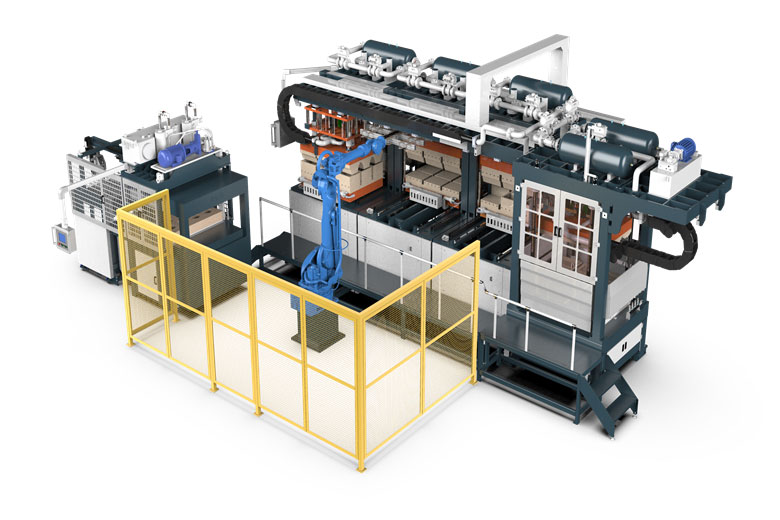

Automatic Molded Pulp Tray Forming Machine HM-ZX1614

Automatic Molded Pulp Tray Forming Machine HM-ZX1614 was launched in 2018, the finished product application is good for environmental protection, it can be recyclable, eco-friendly, sustainable.

Automatic Molded Pulp Tray Forming Machine HM-ZX1614 is extensively used for all kinds of package industry, such as luxury package、food industry package、beverage industry package、tableware tools、Flowerpot package and etc

Description:

This machine is a two-stage Molded Pulp Tray Forming Machine developed by our company, can be produced in seperately or on-line production, widely used in molded tableware, high-quality electric products, drawing mold slope of 1.5 degrees and other products.

Automatic Molded Pulp Tray Forming Machine HM-ZX1614 Workflow

1,The steel beam structure: adopts high-quality carbon steel material after welding and annealing process, enhance the stability of the machine。

2,The hot-pressing template adopts nodular cast iron to ensure strength and rigidity requirements。

3,The parts directly in contact with wet pulp are made of stainless steel: such as conveying pipeline, Pulp tank… etc。

4,Control system:equipped with positive and negative pressure control system, which is conducive to semi-finished products and finished product demoulding。

5,Cleaning system: the surface of the die is sprayed with high pressure water, and the rough edge of the product is sprayed with low pressure water。

6,After hot pressing, the product is placed on the conveyor belt by turning mechanism。

7,The machine adopts PLC+ touch screen man-machine system for suction time, hot pressing time, platform position movement… and other production setting parameters。

8,Heat source: electric heating。

9,The whole production process is composed by three setions, Pulp section, hot pressing section, flip output part, In the Pulp Suction section: the pulp is adsorbed on the pulping die, and then prepressed,and then moved to the hot pressing section。In the hot pressing section: the prepressed wet billet is transferred to the hot pressing mold, then formed by hot pressing at high temperature and drying。In flip output part: the hot pressed product will be transferred to the conveyor belt。

Get a Cost-Effective Box Making Machine Solution

Looking for an affordable and efficient solution for your box making needs? Look no further than our cost-effective box making machines. Our machines are designed to provide high-quality, reliable performance at a price point that won’t break the bank. With advanced features and intuitive controls, our machines make box production easy and efficient. So why wait? Contact us today to learn more about how our box making machines can help you streamline your operations and save you money.