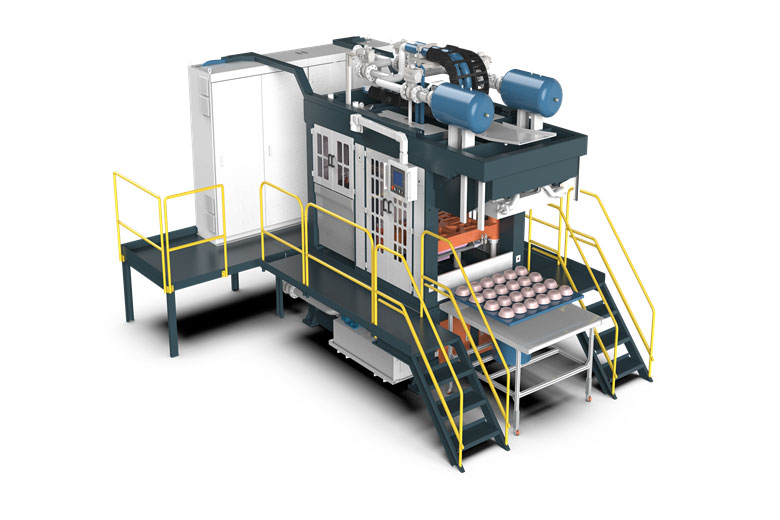

Automatic Molded Fiber Pulp Making Machine

The Automatic Molded Fiber Pulp Making Machine uses molded fiber pulp technology to create trays, boxes, and packaging materials. It is extensively used for all kinds of package industry, such as luxury boxes package、food package、beverage package、tableware tools、Flowerpot package and etc.

It has a versatile, one-mold capability and features an automatic drying system and water control system that increases efficiency. The user-friendly interface allows for easy adjustments and preset configurations.

It is a top choice for businesses prioritizing sustainability and productivity.

Features & Advantages

01. Automatic operation with high efficiency

Automatic Molded Fiber Pulp Making Machine is designed to work seamlessly with minimal human intervention. This means that the machine is fully automated, reducing the need for manual labor and increasing production efficiency. With this feature, production capacity is maximized and production cycles are shortened.

02. Easy maintenance & low operating costs

Automatic molded fiber pulp making machines are generally easy to maintain, thanks to their high-quality components and sophisticated technology. This means that operators can easily and quickly troubleshoot and maintain the machine, which ultimately helps to reduce maintenance costs.

03. Wide range of applications

This machine is designed to produce a diverse range of molded fiber products, including pulp trays, egg trays, fruit trays, and many other products. This versatility makes it ideal for manufacturers who want to diversify their production lines.

04. Environmentally friendly and sustainable

Automatic Molded Fiber Pulp Making Machine utilizes recycled paper products as raw materials, which is a sustainable and environmentally-friendly production process. In addition, it reduces the landfill wastes and carbon emission during the production process.

05. Saves time and labor costs

With automatic operation, the machine eliminates the need for manual intervention in the production process, resulting in much faster production. This not only saves time but also reduces labor costs since fewer operators are required to run the machine.

06. Consistent & reliable quality Products

The automatic molded fiber pulp making machine delivers consistent and reliable quality of products since it is designed to maintain a consistent production process every time. This means that you can expect high-quality molded fiber products every time you run the machine.

07. Customizable to meet specific production requirements

Automatic molded fiber pulp making machines can be customized to produce a wide variety of molded fiber products, including trays, egg cartons, and other shaped products. The machine can also be customized to produce a range of colors and designs to meet specific production requirements and brand standards.

08. Reduces waste and promotes recycling of paper products

Automatic molded fiber pulp making machines use recycled paper products as raw materials, which helps promote recycling, reduce the environmental impact of production, and ultimately reduce waste. Additionally, the molded fiber products produced by the machine are also eco-friendly and biodegradable, which promotes sustainability.

Technical Comparison Among Our Machines

| Specs/Model | HM-ZX1080 | HM-ZX1614 | HM-ZX1310 |

|---|---|---|---|

| Power | |||

| Dimensions | |||

| Output Capacity | |||

| Electricity | |||

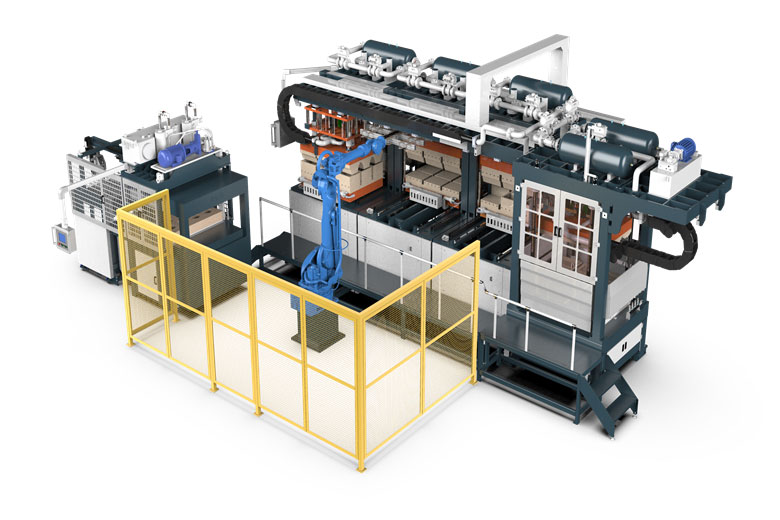

Application Cases

High-end Pulp Moding Machines, Your trusted Supplier

Discover our exceptional range of high-end pulp molding machines, designed to meet the most demanding requirements. As your trusted supplier, we provide innovative solutions that ensure top-quality and efficient production of trays, boxes, and packaging materials using advanced molded fiber pulp technology.