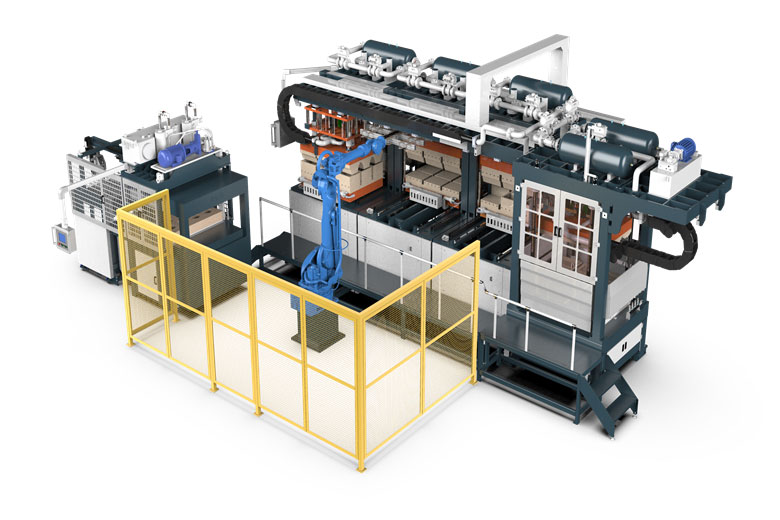

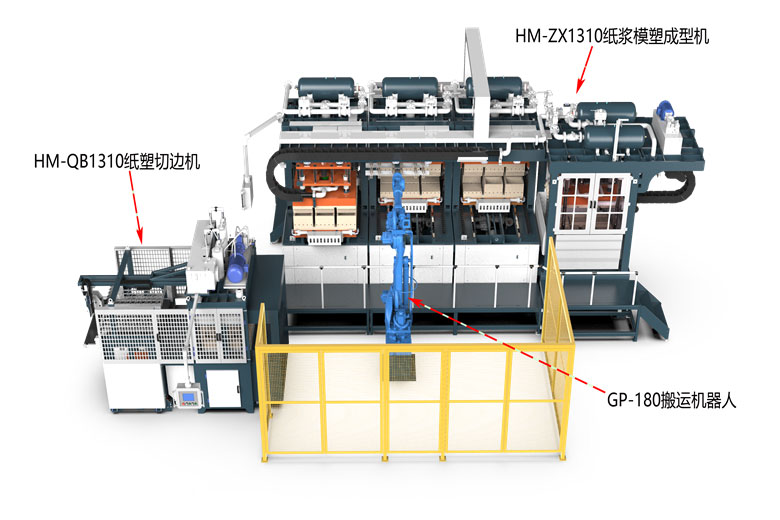

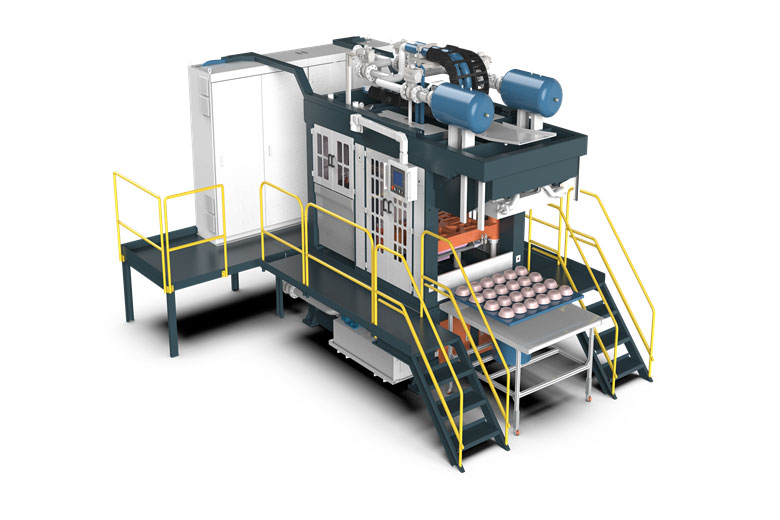

Automatic Molded Fiber Pulp Forming Machine HM-ZX1310

Automatic Molded Fiber Pulp Forming Machine HM-ZX1310 was launched in 2019, the finished product application is good for environment protection, recyclable, eco-friendly, sustainable.

Automatic Molded Fiber Pulp Forming Machine HM-ZX1310 is extensively used for all kinds of package industry, such as luxury boxes package、food industry package、beverage industry package、tableware tools、Flowerpot package and etc

Description:

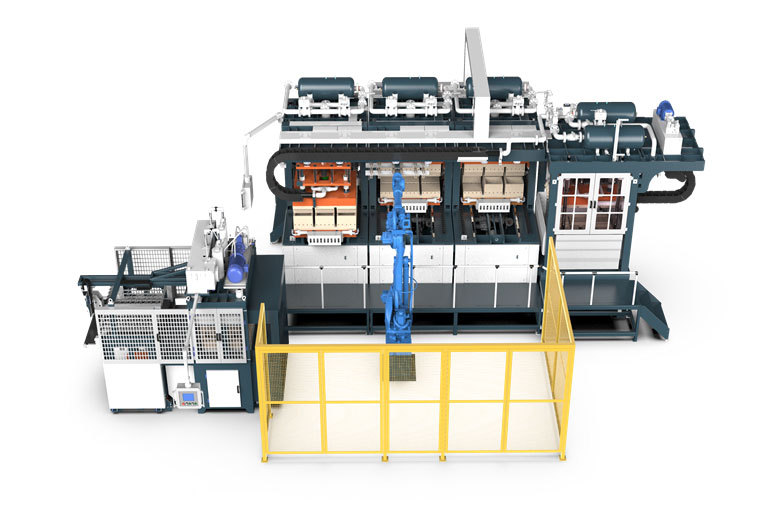

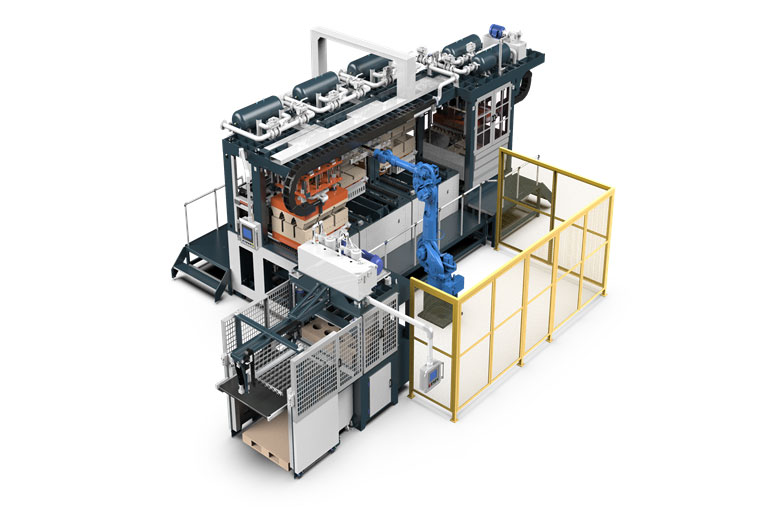

The whole production process is composed of four sections, Slurry section; Hot-pressing 1st section; hot-pressing 2nd section; and hot-pressing 3rd section. In the slurrying section, the oil cylinder moves 500m, after Wet Pulp Moving Mold is scooped up, the slurrying section will complete the drying and pressing, then the pressing mold will be removed off(this mold only for repressing the hot-pressing section will prepress wet pulp and move it to hot-pressing mold (in this part, the hot-pressing section share the wet pulp moving mold). The wet pulp moving mold adopts a servo motor to control, one supply three, greatly improving the production efficiency. The machine adopts direct hot-pressing and drying forming technology, no need to use the oven.

The steel beam structure: adopts high-density carbon steel material after welding and annealing process, enhance the stability of the machine

The parts directly in contact with wet pulp are made of stainless steel: such as forming platform, pulp storage barrel… etc

Machine template area(LengthxWidth): 1300x1000mm

The moving distance of hot-pressing mold: 1100mm, adopts servo motor

The mobile power of the platform under pressing platform is driven by hydraulic pump, and the moving distance is 500mm

The vertical moving power of the hot pressing platform is driven by a hydraulic pump, and the mold force is 35 tons. Vertical moving distance is 450 mm, the height size of the product is up to 150mm

The upper and lower hot-pressing platforms of the machine are equipped with water cooling plates to increase the accuracy of the upper and lower clamping

The machine is equipped with stable blowing and suction system and vacuum system, as well as semi-finished product delivery and finished product demoulding

The machine is equipped with high and low-pressure water sprinkler systems: high-pressure water sprinkler to clean the mold net surface, low-pressure water sprinkler to clean the product rough edges

The receiving table is equipped with a vacuum suction cup, automatically turn over and receive the material and transport output

The machine control mode adopts programmable controller(PLC)+touch type man machine interface, which can adjust hot pressing time, platform and suction time, etc.

Average pulp consumption of the machine depends on the product.

The actual power consumption of the machine depends on the product

Machine heating source electric heating.

Get a Cost-Effective Box Making Machine Solution

Looking for an affordable and efficient solution for your box making needs? Look no further than our cost-effective box making machines. Our machines are designed to provide high-quality, reliable performance at a price point that won’t break the bank. With advanced features and intuitive controls, our machines make box production easy and efficient. So why wait? Contact us today to learn more about how our box making machines can help you streamline your operations and save you money.